Elevating Water Exchangers through Expert Welding

In the realm where mechanics and precision intertwine, lies the craft of welding water exchangers. This intricate process involves merging the efficiency of heat transfer with the finesse of skilled welding. Through the calculated fusion of metal components, we breathe life into a vital element of systems reliant on temperature control.

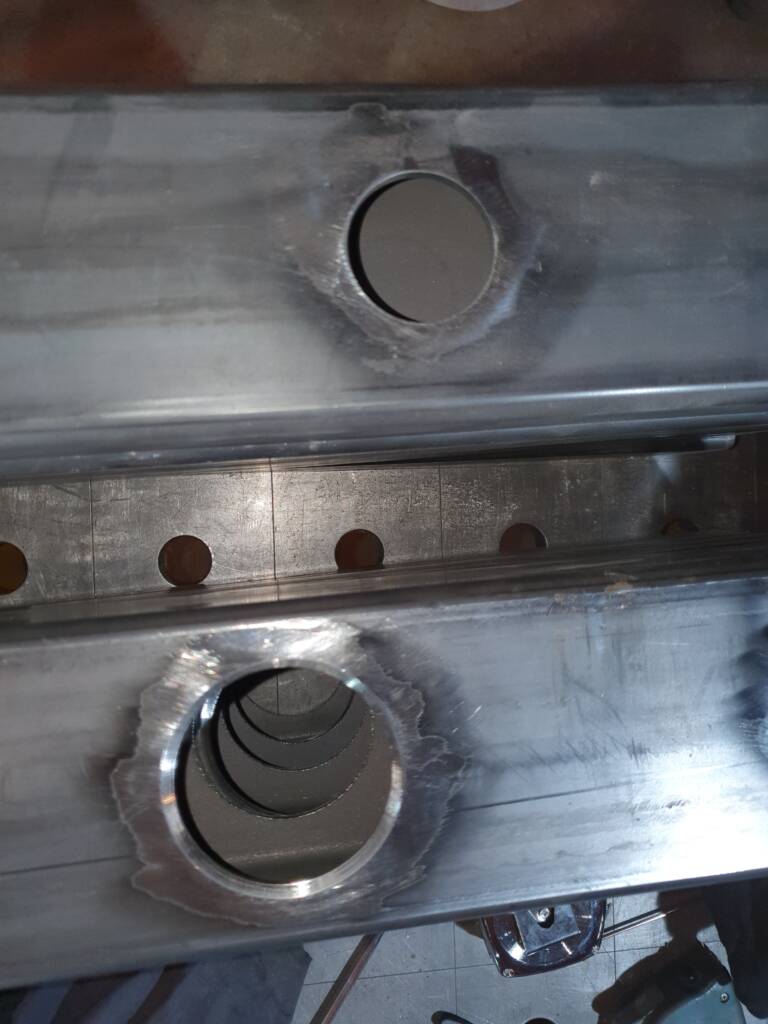

Our journey begins with meticulous material selection, a critical foundation for the exchanger’s functionality. As the pieces come together, our expert welders employ advanced techniques to create seamless connections, ensuring that every joint stands resilient against the flow of water and the challenges of varying temperatures.

The precision of our welds not only guarantees structural integrity but also optimizes the exchanger’s efficiency. Each weld is a testament to our commitment to quality, resulting in an assembly that excels in performance, durability, and longevity.

Beyond the technical intricacies, this process is a harmonious collaboration between innovation and tradition. It’s about understanding the fluid dynamics within, ensuring every weld contributes to the overall efficiency of the system.

The artistry of our welding goes beyond function – it’s about creating a water exchanger that becomes an integral part of a larger mechanical symphony.

From intricate soldering to strategic joint placement, our team leaves no detail untouched. The water exchanger emerges not just as a component but as a testament to the mastery of our craft, a tool that enhances the efficiency of industries reliant on precise temperature control.

In the end, welding a water exchanger isn’t just about joining metals; it’s about orchestrating an intricate dance of heat, pressure, and material.

It’s about refining the science of exchange and infusing it with the artistry of welding. The result is a symphony of form and function, a mechanical masterpiece that elevates industries and stands as a hallmark of our expertise.